Laser welding

Laser

Speed of light. You don’t become an innovation leader overnight. It takes intensive research and development. And the human factor is often the key. In our case, it's the talent of our developers to combine ideas. Thanks to them, we offer the most advanced welding process currently available: LaserHybrid. This system unites the benefits of laser beams with those of MIG welding. The result is a welding process that can operate at a phenomenal speed, advancing at 9 m/min.

LaserHybrid

|

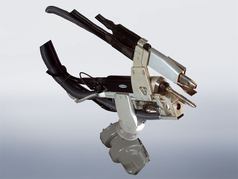

In the Laser Hybrid process, the laser beam and the arc act in the welding zone at the same time, and influence each other. The results are welcome synergy effects: highest possible speed, with the highest possible quality, stabilisation of the process, and spatter-free welding, even at maximum speed; improved gap bridgeability, less distortion and therefore less rework and shorter production times. A newly developed welding head for fully automatic applications has minimum geometrical dimensions, providing easy access to components which are difficult to weld. With the Laser Hybrid process, aluminium, steel, galvanized steel and high-grade steels up to a thickness of 4 mm can be welded.

Base metals

Structural steels, CrNi steels, ferritic/austenitic, duplex steels, aluminium materials, magnesium materials, special materials, galvanized sheet metal

Fields of use

Plant and container construction, mechanical engineering, steel engineering, automobile and component supply industry, aerospace industry, tracked vehicle manufacturing

LaserHybrid + Tandem

|

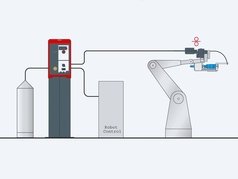

Laser Hybrid + Tandem welding is an automated high-performance welding process, in which the Laser Hybrid process is combined with the Tandem welding process. The combination of a laser beam with three arcs, opens up new dimensions in the joining of heavy gauge metallic sheet materials: high welding speeds with good gap bridgeability and good metallurgical characteristics.

The preliminary LaserHybrid process with one arc creates a very narrow heated zone with a great weld-depth to seam-width ratio. The following Tandem welding process has considerably less concentrated energy, and is characterised by a very high deposition rate. Steel sheets up to 8 mm thick can be welded with increased welding speed.

The preliminary LaserHybrid process with one arc creates a very narrow heated zone with a great weld-depth to seam-width ratio. The following Tandem welding process has considerably less concentrated energy, and is characterised by a very high deposition rate. Steel sheets up to 8 mm thick can be welded with increased welding speed.

Base metals

Structural steels, ferritic/austenitic, duplex steels, aluminium materials

Fields of use

Plant and container construction, mechanical engineering and steel engineering, automobile and component supply industry, tracked vehicle manufacturing

Laser Hotwire

|

With Laser Hotwire, the laser beam heats the base metal. The pre-heated wire is fed in, and brazed or welded with the base metal. The results are welcome synergy effects: highest possible speed with highest possible quality, stabilisation of the process and spatter-free welding and brazing, even at maximum speed. Less distortion and less seam volume, and a better seam surface guarantee shorter production times and less reworking.

Base metals

Cr/Ni steels, ferritic/austenitic, duplex steels, special materials, galvanized sheets

Fields of use

Plant and container construction, mechanical and steel engineering, automobile and component supply industry, aerospace industry, tracked vehicle manufacturing

Cold Wire

|

With Laser Coldwire, the laser beam heats the base metal and the filler metal, and welds or brazes them together. This achieves the greatest possible stabilisation of the process, high quality, spatter-free welding and less distortion. This saves rework and reduces production times.

Base metals

Cr/Ni steels, ferritic/austenitic, duplex steels, special materials, galvanized sheets

Fields of use

Plant and container construction, mechanical and steel engineering, automobile and component supply industry, aerospace industry, tracked vehicle manufacturing

Are you interested in this product? Contact us using form below or contact us directly on e-mail info@mrs.cz or call +420 545 175 844 or +420 602 707 001.